Rope Behaviour Under Load

When a rope is subjected to axial loads, the elasticity of the material will cause elongation and consequential diameter reduction.

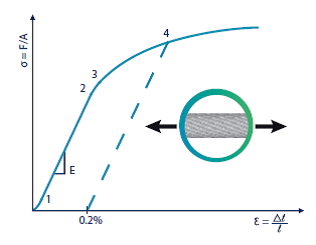

This behaviour is summarized in the first figure, which shows the relationship between stress (the ratio between applied load and metallic area) and strain (ratio between elongation and initial sample length), while the slope of the curve represents Young modulus “E”.

In the first phase of its use (up to point 1), rope shows a certain permanent stretch due to the stabilization of the individual wires. After this step, the trend is basically linear up to the achievement of yield point (points 3 and 4), from which point permanent plastic deformation takes place, until the load reaches the actual rope breaking force.

As already mentioned in the section "Strength & Breaking Force", a good rope composed of ductile wires must have a long elastic area to ensure safe working conditions.

Rope diameter shows a permanent reduction after the first utilization cycles; the trend is shown in the second figure.

Copyright © 2014 Brunton Shaw. All Rights reserved.

Copyright © 2014 Brunton Shaw. All Rights reserved.